In 1993, the Lachman brothers founded a company that has developed into the most important custom furniture manufacturers in the Czech Republic within 25 years.

It deals with the processing of solid wood, veneer, flat materials with laminate surfaces, fireproof boards and polymer stone.

The symbiosis of carpenters’ experience and production with state-of-the-art technologies and quality partners has led to hundreds of satisfied clients around the world.

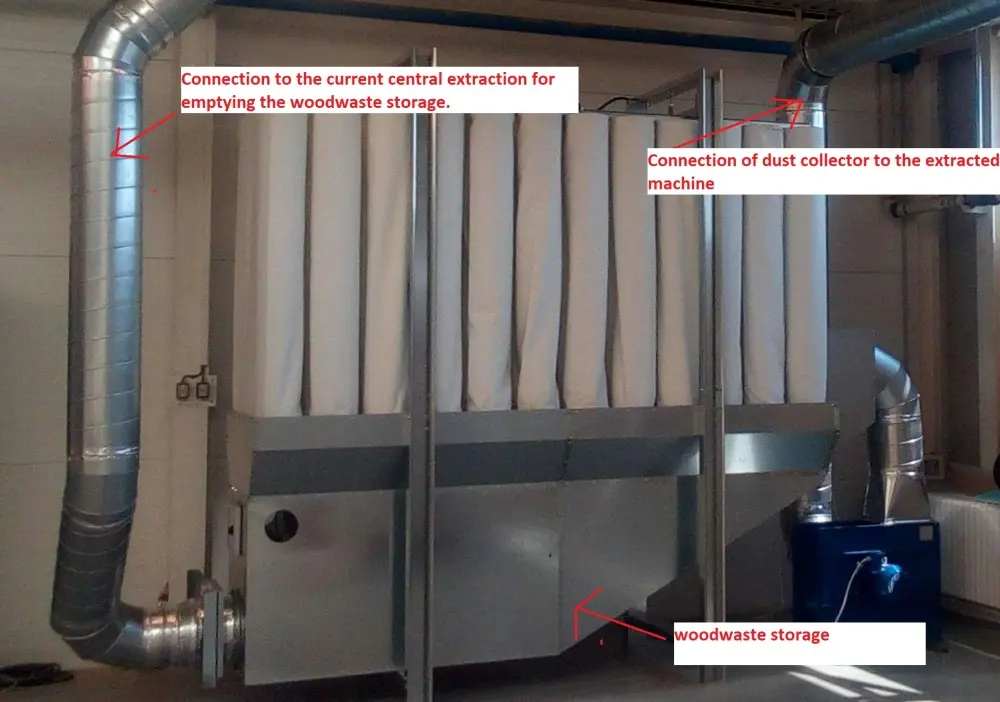

Mr. Lachman approached us at the end of 2018 with a request for a solution for the extraction of three CNC machines and an automatic doweling machine. The Lachman company has a central extraction system, but unfortunately this unit no longer had sufficient capacity to connect new CNC machines and dowel pins, and therefore these machines were extracted by local bag dust collectors. Insufficient performance and dust when emptying the bags were the main reason why Mr. Lachman was looking for a different solution.

Increasing the central extraction capacity would be technically and financially demanding, which is why we proposed strengthening the extraction capacity using a separated FT 650 LZ unit with a container, which is emptied into the existing central extraction system after the shift is completed. The extraction capacity of the central extraction unit was thus increased and at the same time we solved the need to dispose of bagged waste.

This system has been operating for over a year to the full satisfaction of owners and employees.